How are vinyl records made in factory?

2023-02-22 15:37

Vinyl records are making a comeback, and it's not just because of their nostalgic appeal. Audiophiles and music lovers alike appreciate the warm, rich sound that vinyl provides. But have you ever wondered how vinyl records get made? From the factory to your turntable, let's take a closer look at the process.

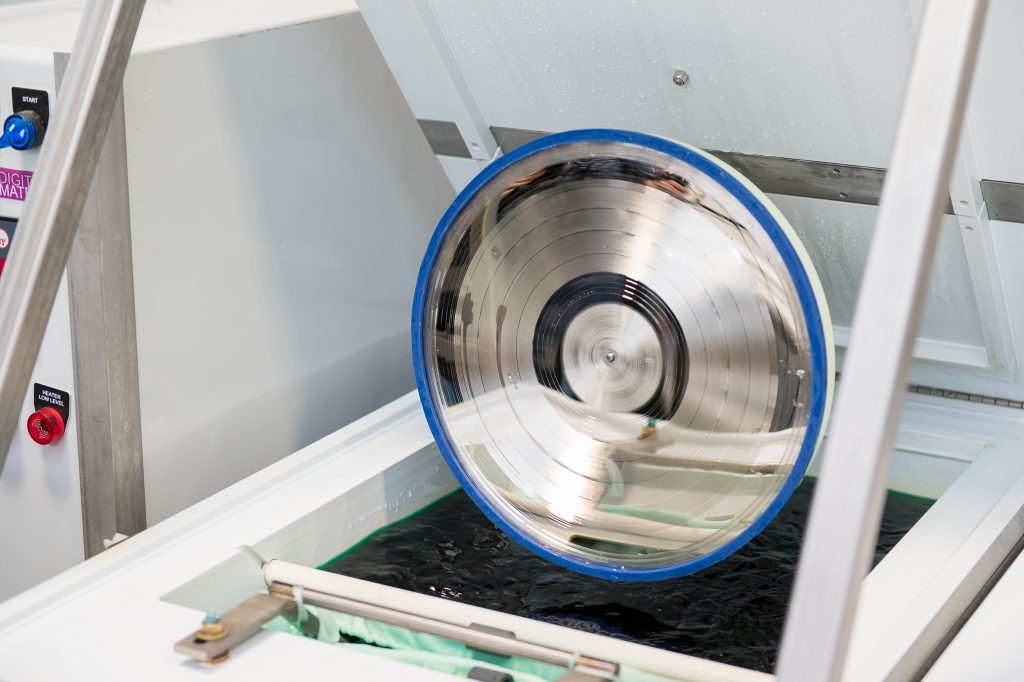

At the heart of vinyl production is the record pressing plant. These plants are responsible for taking the music that has been recorded and mastered, and turning it into a physical vinyl record. The process begins with the creation of a metal stamper. This is done by coating a lacquer disc with a layer of silver, which is then electroplated with nickel to create a negative image of the music. This negative is then used to create a positive image on another metal disc, which is the stamper that will be used to press the vinyl records.

Once the stamper is created, it's time to press the records. The vinyl is heated up and placed between the two stampers. The stampers are then brought together with intense pressure, which causes the grooves to be pressed into the vinyl. As the vinyl cools, it hardens and the grooves become permanent. This process is repeated for each record in the batch, and the result is a set of identical vinyl records.

But not all vinyl records are created equal. Many artists choose to have custom vinyl records made, which allows them to stand out from the crowd. This can include colored vinyl, picture discs, or unique packaging. To create these custom records, a special process is used that involves adding the color or image to the vinyl before it is pressed. This allows the image or color to be embedded into the vinyl itself, creating a unique and long-lasting effect.

Another important factor in vinyl production is the size of the record. Most records are 12 inches in diameter, but there are also 7 inch and 10 inch records. The larger the record, the more music that can be included on each side. This is because the grooves can be cut wider and deeper, allowing for more information to be stored on the record. However, larger records are also more expensive to produce, which is why many artists choose to release their music on smaller records.

In conclusion, the process of creating a vinyl record is a complex and intricate process that requires a combination of technical expertise and artistic vision. From the initial mastering process to the pressing and customizations, every step of the process plays a critical role in creating a high-quality vinyl record that will stand the test of time.

DESHENG is China's fastest vinyl factory offering vinyl record customization services with a delivery time of 20-28 days. We guarantees high-quality records at a low price, making it an attractive option for music lovers who want to create our own unique vinyl collections. We have a team of skilled professionals who work tirelessly to ensure that customers receive the best product possible. We use cutting-edge technology and techniques to manufacture records and constantly innovating to stay ahead of the competition. If you're looking to create your own vinyl record, DESHENG is the perfect place to start.

Despite the rise of digital music, vinyl records continue to be a popular choice for music lovers. There's just something special about holding a physical record in your hands, carefully placing it on the turntable, and listening to the warm, rich sound that it produces. Whether you're a collector, an audiophile, or simply a music lover, vinyl records offer a unique and timeless listening experience.

Get the latest price? We'll respond as soon as possible(within 12 hours)